BREITNER

Packaging machine solutions

for cleanliness, sterilisation and air purity

With decades of experience in the development of packaging machines, our engineers ensure that production processes remain efficient, hygienic and reliable. We use this expertise to tailor each filling solution to your individual requirements.

Regular cleaning is also one of the decisive factors in production. In most cases, it is necessary to thoroughly clean the filling machine at the end of a shift. To this end, we develop practical solutions that minimise downtime while meeting high hygiene standards.

Packaging machine solutions for cleanliness, sterilisation and air purity:

Our systems take into account all aspects of modern packaging solutions – from hygienic design and cleaning processes to ensuring air purity in sensitive production environments. The result is durable, safe and efficient industrial filling solutions that meet the growing demands of the food, pharmaceutical and cosmetics industries.

CIP – Cleaning in Place

What exactly does this cleaning process look like? How consistently should the process be automated? What happens to the cleaning medium – is it recycled and disposed of?

We offer you the full variety of technical possibilities.

All these questions depend on the product, environmental requirements for your production plant and the desired degree of automation.

SIP – Sterilization in Place

We provide the necessary technology for sterilising the product flow with hot steam and for sterilising the compressed air used via activated carbon or sterile filters.

Your laboratory staff and our machine technicians work closely together. This ensures the success of sterile operation in your production.

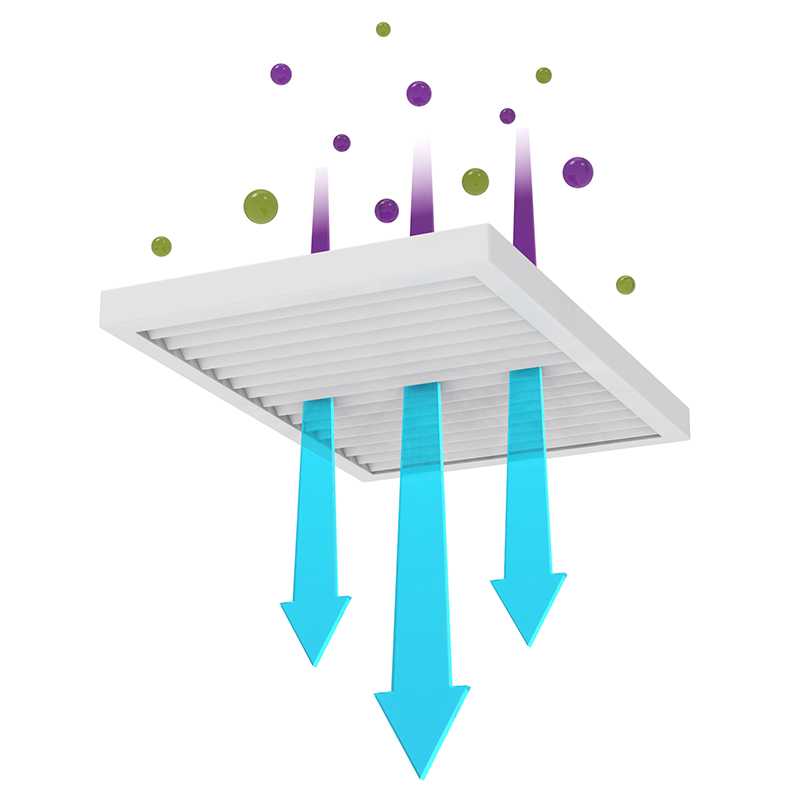

Filtered air around the filling nozzle – laminar airflow

Our machines

for CIP, SIP & laminar airflow

Containers and closures?

No problem, we can handle them all!

Cleanliness, sterilisation & air purity –

hygiene standards with BREITNER

Whether for food, pharmaceuticals, cosmetics or chemicals – wherever purity counts, our systems ensure stable processes and consistently high quality.