BREITNER

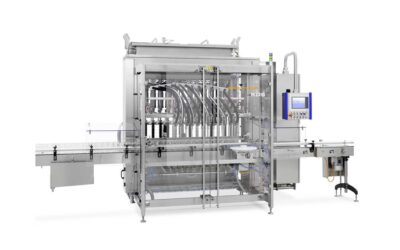

Filling machines & filling systems

Variable filling machines

Different dosing methods &

various designs

flexible, efficient, proven

Filling machines from BREITNER stand for precise dosing, hygienic design, and maximum flexibility. Developed for the automated filling of liquid and paste-like media, our machines are used worldwide in the food, cosmetics, chemical, and household cleaning industries. Whether shampoo, cleaner, cream, or oil – BREITNER offers tailor-made solutions for a wide variety of products and container sizes.

We rely on three proven dosing technologies:

Piston fillers for highly viscous products, flow measurement technology for liquid media, and peristaltic pumps for sterile or sensitive applications. Thanks to intelligent control, robust construction, and easy cleanability, our filling machines can be efficiently integrated into modern production lines – and can be adapted to new requirements at any time.

The highlights of our filling machines at a glance:

-

High dosing accuracy for consistent product quality

-

Short setup times thanks to tool-free format changeover

-

Modular design for individual adaptation to your line

-

Durable components – developed and built in Germany

-

Easy cleaning thanks to smooth surfaces and hygienic design

With BREITNER, you are choosing a machine solution that thinks for itself, grows with you, and impresses with its performance.

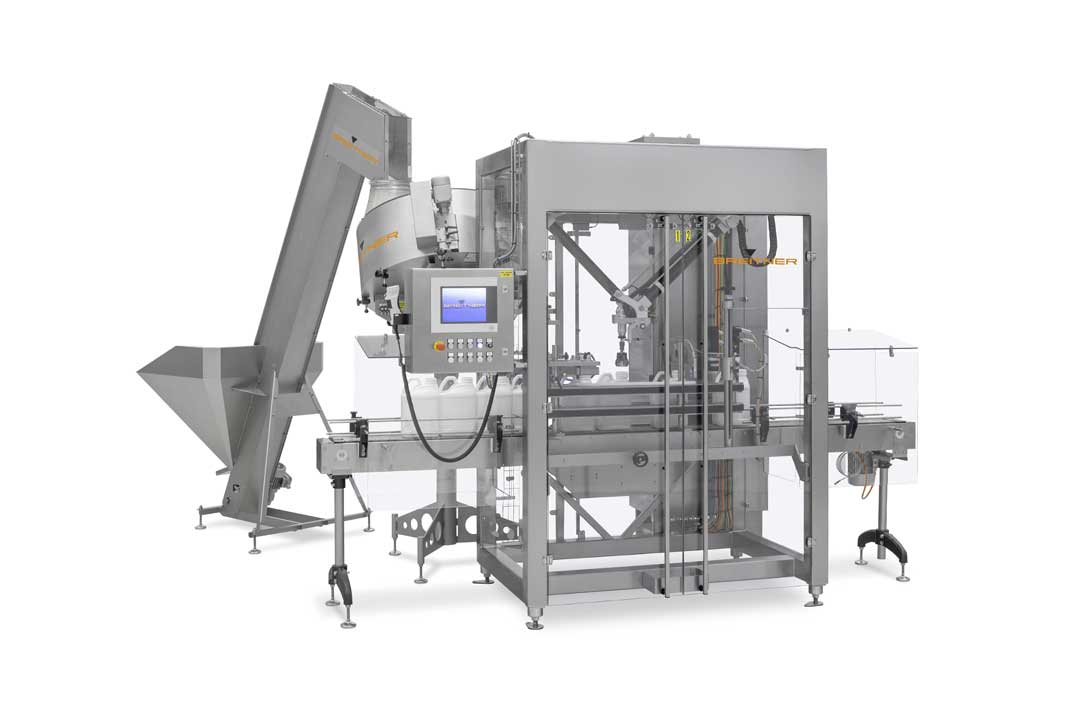

Machine overview

Linear, piston, rotary filling, and

special machines

Our filling systems/machines –

Flexible solutions for every industry

Filling machines – precision meets flexibility

Trust in our decades of experience in the development and manufacture of filling systems for food, chemicals, cosmetics, and many other industries.

Your advantages at a glance

- High filling accuracy and gentle handling of products

- Flexible adaptation to different containers

- Short changeover times and simple operation

- Durable, low-maintenance design

Find the right filling machine now – we will advise you personally and develop your customized solution.

Individual consultation. Tailor-made technology.

Made by BREITNER in Schwäbisch Hall

BREITNER develops individual solutions for food, chemicals, cosmetics, and household cleaners –

precise, reliable, and easy to use. Made in Schwäbisch Hall – used worldwide.