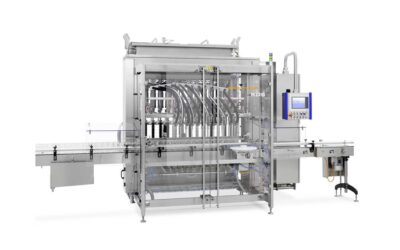

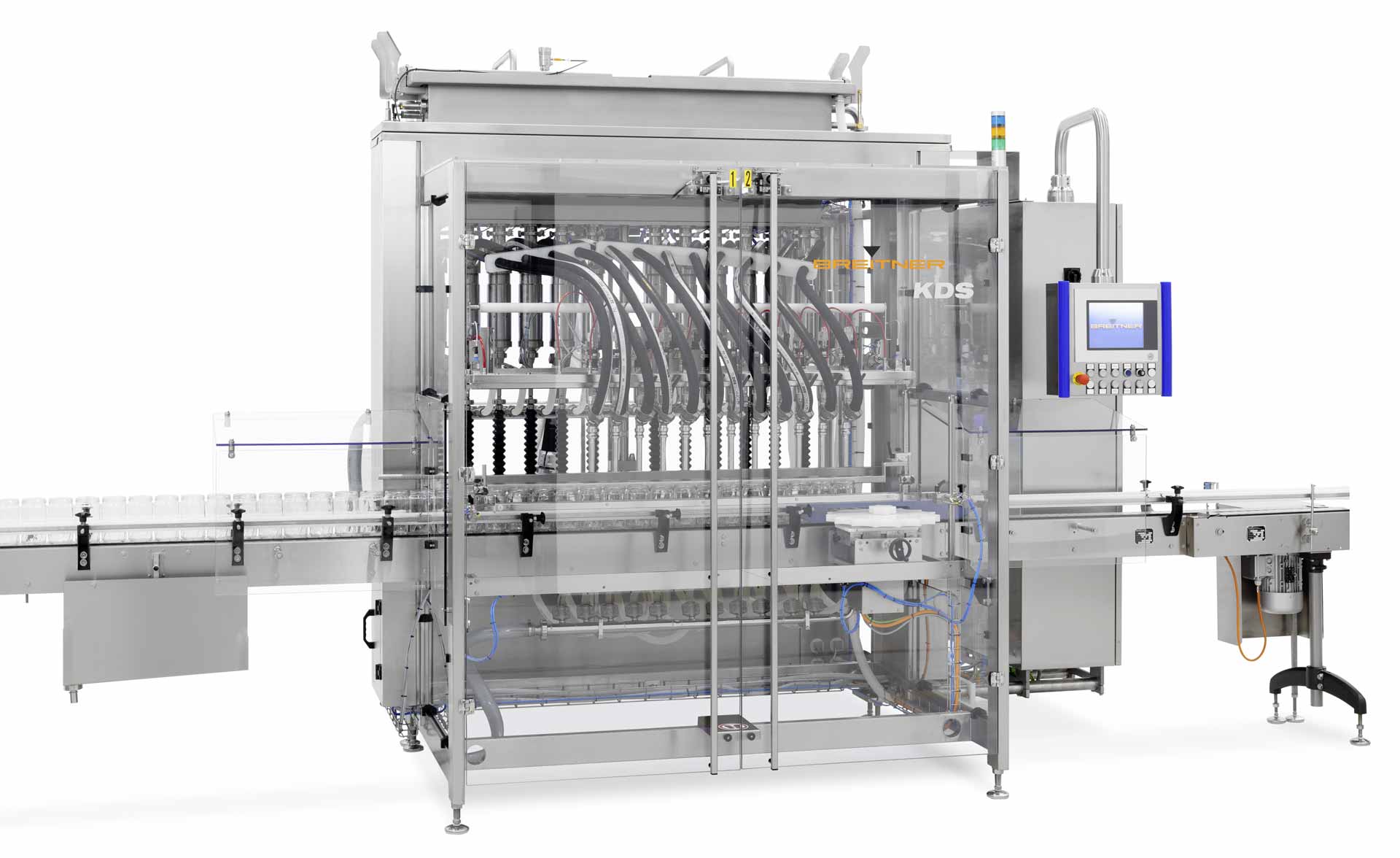

Linear piston filling machine

Type KDS

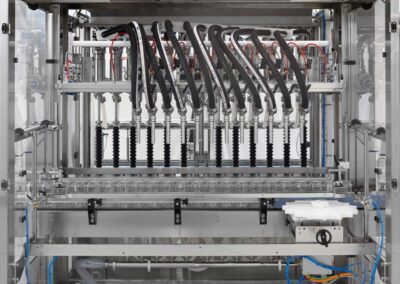

Under- & over-mirror filling with servo drive

Electromechanical servo drive, the metering piston operates precisely and durably

Selectable product container size

Sensor tubes are adapted to containers

Product container with stirrer

Heated product container

Unter- und Überspiegelfüllung mit Servoantrieb

Elektromechanischer Servoantrieb der Dosierkolben arbeitet präzise und langlebig

Größe Produktbehälter auswählbar

Füllrohre werden an Gebinde angepasst

Produktbehälter mit Rührwerk

Beheizter Produktbehälter

Technical data

Piston filling machine

for liquid to paste-like products –

from food to cosmetics

The precision-engineered piston fills each bottle with the utmost accuracy.

Thanks to their modular design, the linear filling machines can be individually adapted to different container shapes and production requirements. This allows you to combine efficient processes with maximum product quality.

Easy cleaning & maintenance

The linear piston filling machine is designed for hygiene and quick cleaning. Parts that come into contact with the product can be easily dismantled and cleaned, ensuring the highest standards, especially in the food and cosmetics industries.

The piston technology ensures precise volume dosing—even with highly viscous products. This reduces product losses and rework to a minimum.

Flexible application options

Whether small or large batches, liquid or viscous products: the piston filling machine impresses with its universal application areas and fast changeover times.

Future-proof technology

Thanks to modular expansion options, the piston filling machine can be adapted to increasing production requirements at any time. This means you are investing in a solution that guarantees maximum efficiency in the long term.