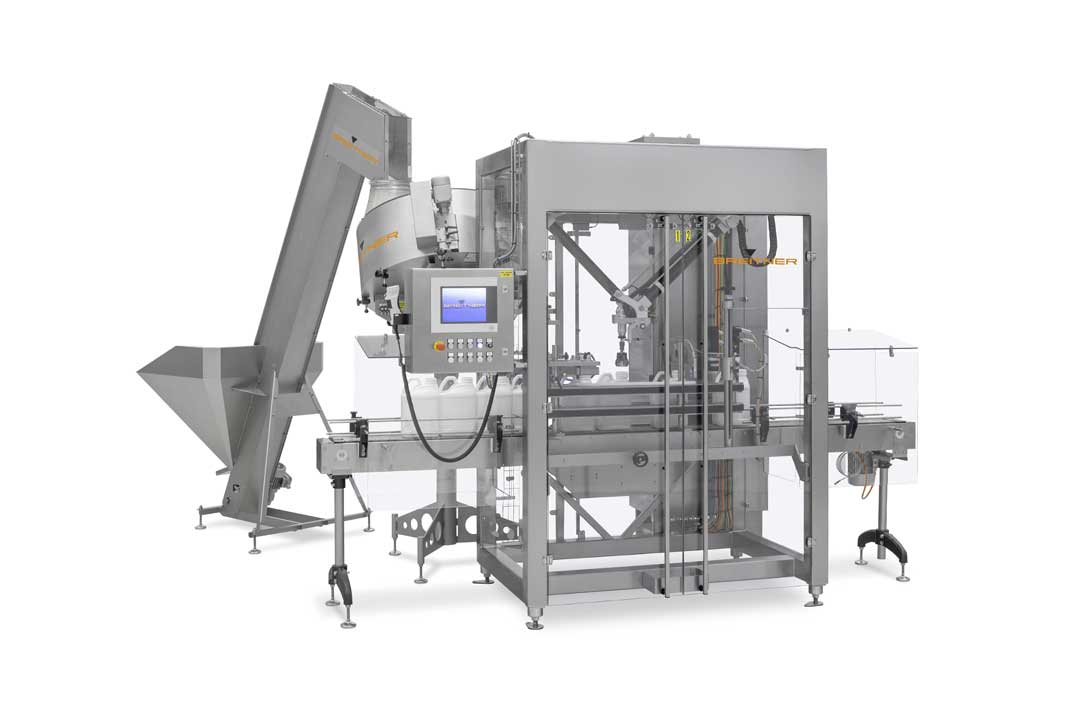

BREITNER

Packaging machine solutions

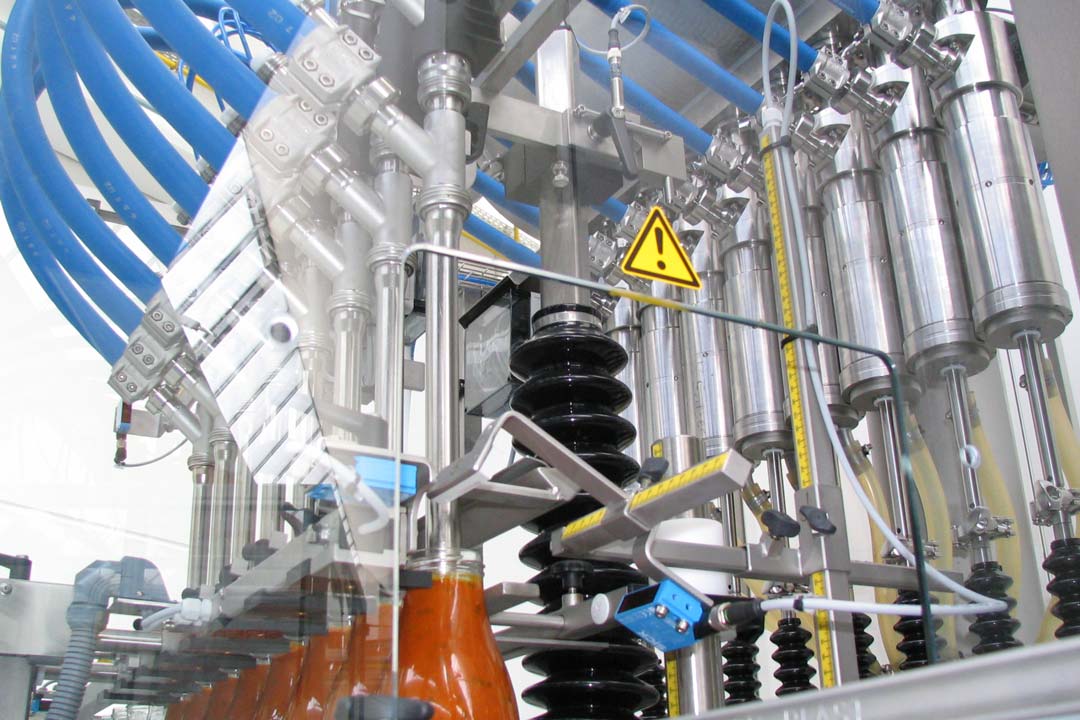

Our filling nozzles for filling levels

The BREITNER machine control allows settings that make the filling process particularly clean and fast:

Overspill filling the opening of the filling nozzle is always at the same distance above the liquid level. This is also the case with tapered bottles (moulded bottles), where the rise of the liquid level varies during the filling process.

Filling below the level here the opening of the filling nozzle is always just below the level of the liquid. This makes it easy to fill even highly foaming products.

Our machines

for all filling nozzle &

an optimal fill level

Containers and closures?

No problem, we can handle them all!

Filling nozzles & filling levels –

Precision in every container

BREITNER packaging machines are designed to reliably implement a variety of filling processes – from classic piston filling to overfill filling. This ensures that every container is filled cleanly, precisely and gently.

Thanks to state-of-the-art sensor technology and intelligent control technology, the fill level is monitored with the highest precision.

Precise dosing

Clean filling level

Frequently asked questions

Our answers

Which filling nozzles are suitable for my products?

How can I clean my filling nozzles or convert them for use with a different product?

All filling nozzles are designed to be quick and easy to dismantle. Depending on the machine type, CIP or SIP cleaning is possible. The filling nozzles can be easily cleaned for product changes – efficiently, hygienically and in a time-saving manner.