BREITNER

Packaging machines for setting up, filling, and closing

We package liquid products!

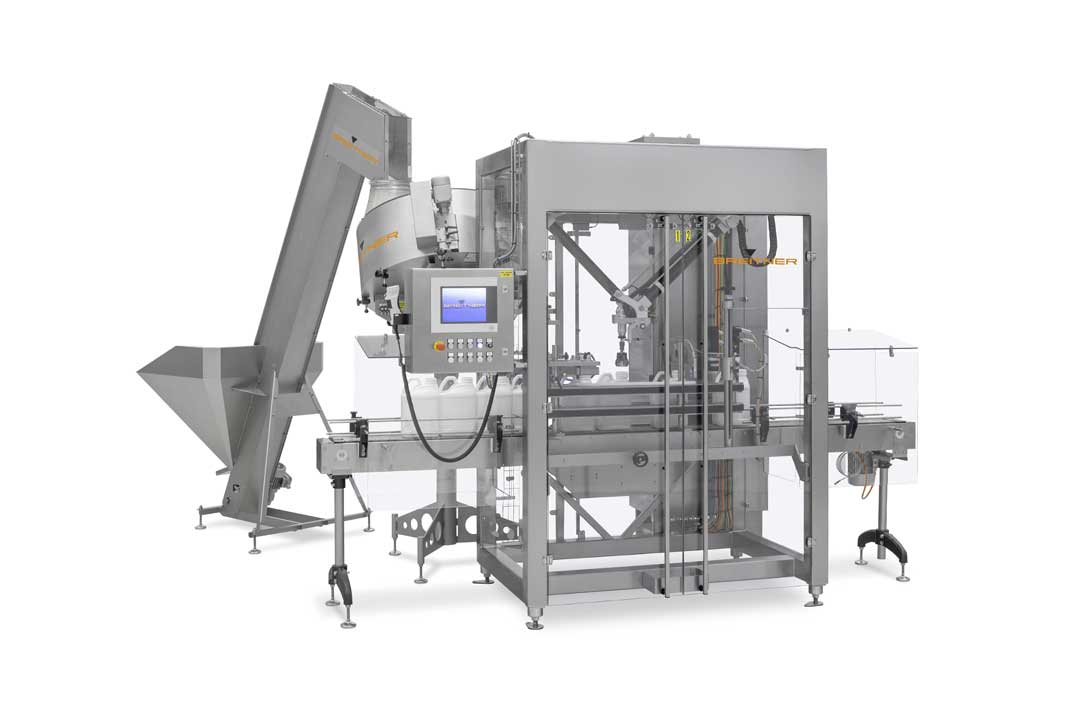

From bottle setters to filling systems and machines to closing machines, we cover all the core processes involved in filling. We supply individual packaging machines or complete filling systems.

Why are we experts in filling and closing?

Our customers come from four industries: chemicals, food, cosmetics, and pharmaceuticals. These industries have different priorities when it comes to their process requirements. Our company and our engineers have been focusing on these requirements for decades.

The result: BREITNER now has a comprehensive mastery of filling and closing: efficient, flexible for a wide range of requirements, particularly economical, or in the high-performance sector.

BREITNER

Packaging machine portfolio

BREITNER

Solution technologies

Flexible

as standard

Our linear bottle unscramblers, filling systems & machines, and closing machines offer such a wide variety of configurations and adjustment options that our standard packaging machines already cover the majority of our customers’ requirements:

-

From 30 ml bottles to 30 l canisters

-

From 10 containers per minute to 300 (that’s 5 containers per second!) with or without transport forms (used for small bottles or special bottle shapes with low stability) An incredibly wide variety of products, from thin and homogeneous like water to thick like honey, chunky like jam, or sensitive like emulsions

-

Explosion protection if required

-

Cleaning or sterilization concept depending on the product

-

Containers with a wide variety of closures for pressing on, screwing on, with bayonet closures or riser pipes, also in closure combinations; numerous options that cover even exotic applications.

In addition, there are model variants and designs for special requirements for our packaging machines. Here are just the most important ones.

High speed

In the chemical industry in particular—for cleaning agents or motor oil—but also in the food industry, enormous quantities of bottles or cans have to be filled and closed in a short time. This is where our rotary filling machines and rotary closing machines come into play. A highlight: When it comes to pump closures with riser tubes that have to be threaded into the narrow bottle neck, our rotary closing machines are unbeatably fast and precise – and therefore extremely reliable.

Cleaning

In the food and pharmaceutical industries, cleanliness and purity are paramount. With different designs and configurations of our Cleaning in Place (CIP) and Sterilization in Place (SIP) systems, and even air purification processes for filling pipes, we offer economical solutions for moderate requirements and highly effective concepts for exceptional requirements.

Explosion-proof design

Recently, there has been a rush on our explosion-proof filling systems for filling disinfectants. These contain a high alcohol content and are therefore highly flammable. We not only supply the filling machine, but also advise our customers on all aspects of the filling process.

Cost-effectiveness

When considering the transition from manual or semi-automatic filling operations to a fully automated filling and closing system, an analysis of the return on investment will show that the required investment should remain relatively small. BREITNER offers cost-effective entry-level solutions with its Econoline machine family.

Consulting & Project Planning

Which product is to be filled? What does the container look like, especially the closure? 30 ml vials or 30 l canisters? The factor of 1000 in filling quantity and container size leads to highly diverse configurations of our standard machines. How high is the required throughput of the system? How often are batch changes or product changes? Is the product highly flammable and must it be filled under explosion protection conditions?

Our project planning engineers will clarify these and numerous other questions with you in order to arrive at the optimal solution for your product, your production environment, and the economic conditions.

BREITNER family business

It was founded in 1961 by the grandfather of the current management team and has been exclusively owned and run by the family for over 60 years. The next generation is already growing up. Together with the longevity of the machines, this continuity ensures that the company’s customers can still obtain spare parts and service for their machine inventory even after decades.

BREITNER has around 100 employees and is based in Schwäbisch Hall, in the heart of Packaging Valley, an association of over 100 companies in the packaging machine industry that have joined forces on a regional basis and see themselves as the Silicon Valley of the packaging machine industry in Germany.