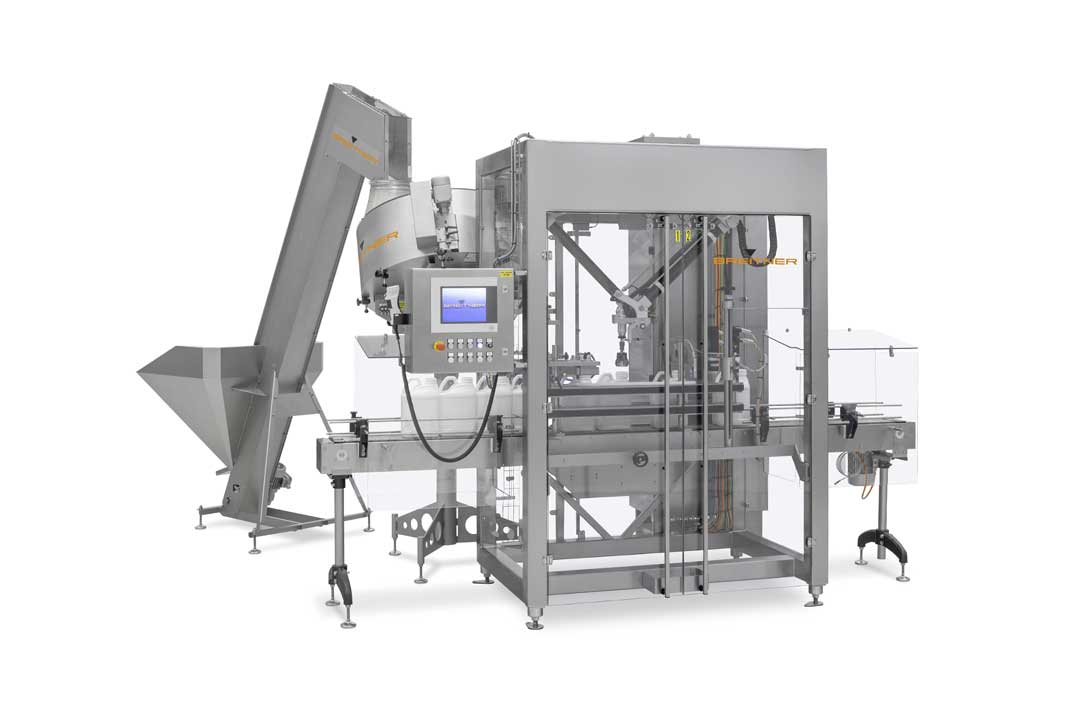

BREITNER Packaging machines for pharmaceutical and medical products

BREITNER offers reliable filling machines and filling systems for non-sterile pharmaceutical and medical products. Our solutions are specially tailored to the high requirements of this industry and combine precision, safety and efficiency.

In addition to development and manufacturing, we naturally provide you with all the necessary documentation for pharmaceutical validation. This enables you to reliably meet regulatory requirements and securely document your production processes.

Another advantage: with our sealing machines for tablet cans, we complement filling lines from other manufacturers to create a complete solution – from precise filling to secure sealing. This results in seamlessly integrated packaging solutions that cover the entire process.

Our industrial filling solutions impress with state-of-the-art filling technology, flexible application options and easy integration into existing production environments. Whether for liquids, powders or solid products, we support you with tailor-made systems that optimally meet your requirements in the pharmaceutical and medical industries.

Rely on our experience as a packaging machine manufacturer and see for yourself the versatile machine solutions ‘Made in Schwäbisch Hall’.

Our machines for pharmaceutical and medical products

Containers and closures?

No matter what, we can handle them all!

Pharmaceutical & Medical Industry Packaging Machines – Maximum Precision and Cleanroom Suitability

In the pharmaceutical industry, precise dosing, seamless process reliability and maximum hygiene are essential.

Whether liquid medicines, syrups, drops or diagnostic solutions – filling and sealing systems must meet the strictest regulatory requirements.

BREITNER packaging machines meet these standards through precise control, validatable processes and a design that is easy to clean.

This is how we ensure that pharmaceutical products are processed reliably, reproducibly and in compliance with GMP – for maximum safety along the entire value chain.

Validated processes for maximum safety

Our filling and sealing solutions for the pharmaceutical industry guarantee reproducible results, quick changeovers and maximum process stability. Cleanroom-compatible designs and validatable systems ensure compliance with all regulatory requirements.

Typical products

- Syrups,

- drops,

- nasal sprays,

- eye drops

- and much more.

Our customers

say about us …

4.7

Based on 26 reviews

powered by Google